Istar Dental Supply

The use of a medical pouch sealer in dental laboratories ensures that instruments remain sterile and ready for use, improves operational efficiency, and supports overall clinic professionalism and patient safety.

Key Features

Improved Sterility

Medical pouch sealer ensures that dental instruments remain sterile, preventing contamination and reducing the risk of cross-infection, thereby significantly enhancing patient safety.

Regulatory Compliance

Medical sealer machine helps dental laboratories comply with stringent health standards set by regulatory authorities and professional organizations. Many advanced sealers come with built-in printers for documenting the sealing process, aiding in regulatory compliance and quality assurance.

Increased Efficiency

Automated and semi-automated sealers speed up the sterilization process, reducing the time and effort required for manual operations, thus improving overall workflow efficiency. They provide consistent and reliable seals, minimizing the risk of human error.

Organization and Management

Sealed pouches are easy to label and organize, simplifying the management and retrieval of instruments. Advanced sealers with printing capabilities make it easier to track sterilization dates and ensure instruments are used within their safe period.

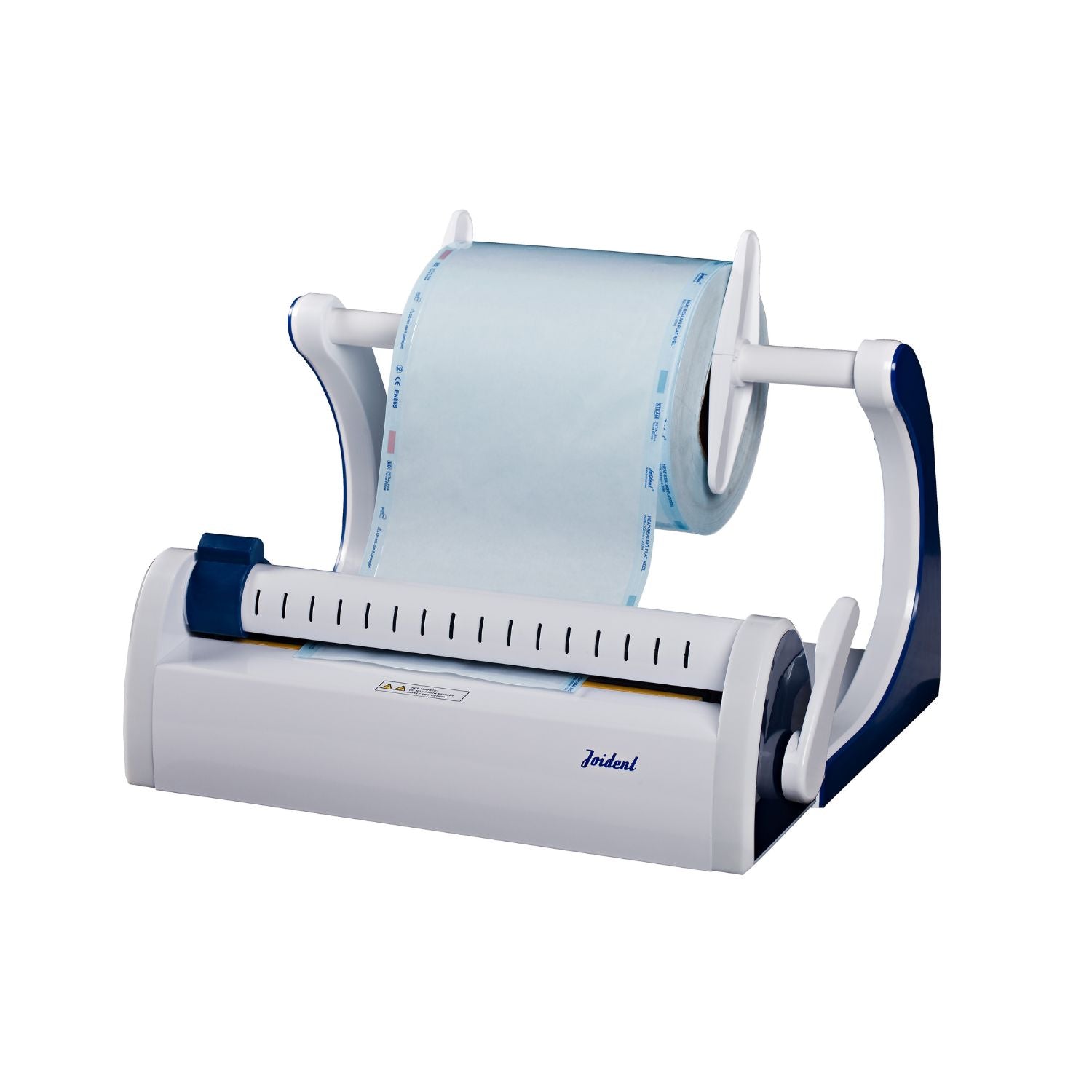

What is a Medical Pouch Sealer?

Medical heat sealer is a specialized device used in healthcare settings to seal sterilization pouches that contain medical instruments and supplies.

These pouches are typically made from medical-grade paper and plastic laminate, and the sealer ensures they are securely closed to maintain sterility until the contents are needed for a medical procedure.

What is the Function of a Medical Sealer?

The primary function of a medical sealing machine is to create a hermetic seal on sterilization pouches.

This seal is crucial for maintaining the sterility of the instruments inside the pouch by preventing the entry of contaminants such as bacteria, viruses, and other pathogens.

By keeping instruments sterile, the sealer helps reduce the risk of infections and ensures that medical tools are safe for use in patient care.

FAQ of Medical Pouch Sealer

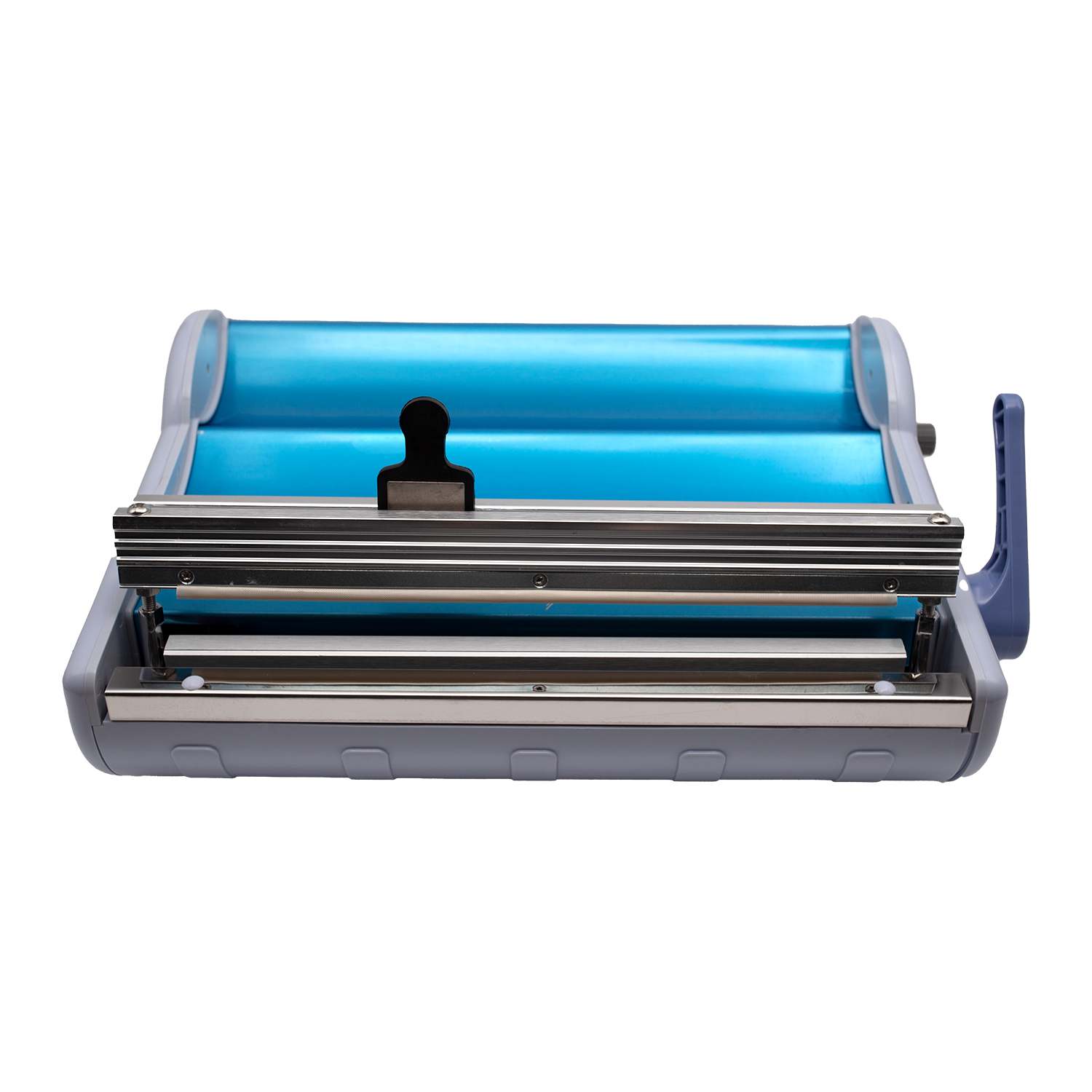

Medical pouch sealing machine operates on the principle of heat sealing. The device typically has a heated element that, when activated, melts the adhesive layer on the sterilization pouch.

The pouch is then pressed between two surfaces, applying pressure and heat to create a tight seal.

Some advanced models use continuous sealing methods where the pouch is fed through a heated roller system for efficient and consistent sealing.

Not every clinic may require a dental sealing machine, but it is essential for those that need to sterilize and maintain the sterility of medical instruments.

Clinics that perform procedures requiring sterile instruments, such as dental clinics, surgical centers, and general medical practices, typically need a pouch sealer as part of their infection control protocols.

Sealing machine dental is used in various scenarios, including:

- Sterilization Departments: In hospitals and clinics, to prepare sterilized instruments for future use.

- Dental Offices: To ensure dental tools are sterile before procedures.

- Veterinary Clinics: For the sterilization of surgical instruments and tools.

- Laboratories: Where sterile conditions are necessary for certain types of research or testing.

- Tattoo and Piercing Studios: To ensure that tools are sterile and safe for use on clients.

The price of a dental pouch sealing machine can vary widely based on its features, brand, and capacity.

Basic manual models may start around $200 to $300, while more advanced, automated, or high-capacity models can range from $1,000 to $5,000 or more.

Factors influencing the price include sealing speed, ease of use, durability, and additional features like built-in printers for documentation.

Medical impulse heat sealer can be classified based on their operation method and features:

- Manual Sealers: Require the user to manually position the pouch and apply pressure to create the seal.

- Semi-Automatic Sealers: Partially automate the sealing process, often with automated temperature and timing controls but manual feeding of pouches.

- Automatic Sealers: Fully automate the sealing process, including feeding, sealing, and often cutting of pouches, suitable for high-volume operations.

- Tabletop Sealers: Compact and designed for smaller clinics or spaces with limited room.

- Industrial Sealers: Larger, more robust machines intended for high-throughput environments like hospital sterilization departments.

Any question?

If we still haven't answered your question, you can contact us below and we will get back to you as soon as possible.