Features:

1. Intelligent Microcomputer Chip Control

The medical pouch sealer is equipped with advanced microcomputer chip to achieve fully automatic control of sealing temperature and time, without manual adjustment, to ensure the accuracy and stability of each sealing, convenient operation, time-saving and worry.

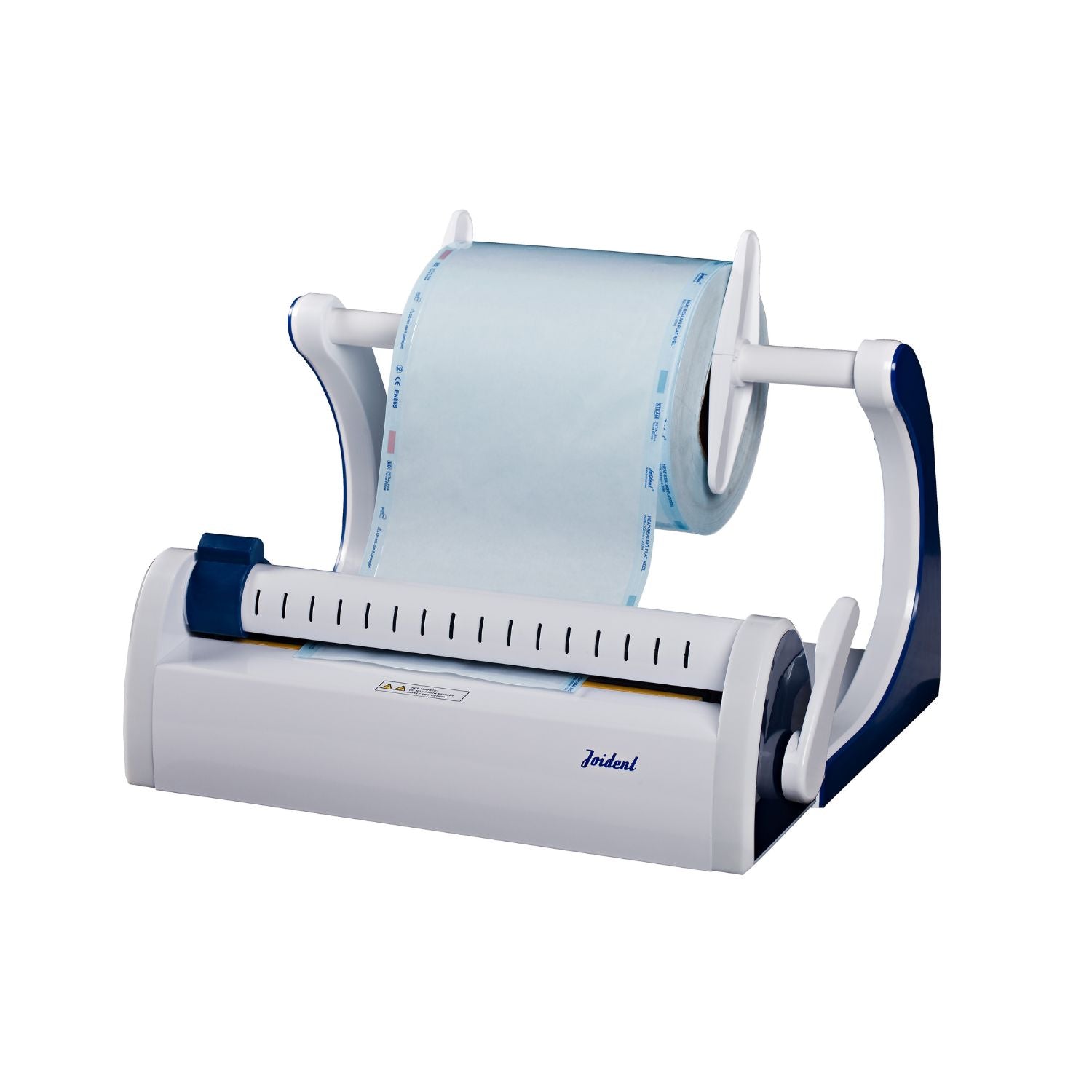

2. Split Bag Holder Design

The medical pouch sealer can flexibly adjust the position of the support according to the width of the sterilization bag, the maximum width is 300mm, and can carry three rolls of sterilization bags at the same time, greatly improving the sealing efficiency, which is suitable for the sealing needs of different sizes of disinfection bags.

3. Safe Sliding Blade

The medical sealer adopts a hidden sliding blade to ensure safe operation, effectively prevent accidental cuts, and provide additional security for users.

4. Automatic Beeping Reminder System

Medical sealer is equipped with front indicator and beeping reminder function, it will automatically remind the user every time the sealing is completed, which is convenient for the operation process management and enhances the working efficiency.

5. Anti-Recoiling And Anti-Scorching Design.

The sealing width reaches 12mm and passes the 30 seconds long pressure test to ensure the sealing is flat and undamaged, effectively avoiding the rewinding and sealing quality of the sterilised bag and ensuring the reliable sealing effect of the sterilised bag.

Parameter:

|

Power supply

|

220V ,110V150HZ,60HZ

|

|

Power consumption

|

100W

|

|

Preheating time

|

2-3min

|

|

Sealing width

|

12mm

|

|

Longest sealing

|

30cm

|

|

Overheat protection

|

Yes

|

|

Packing size

|

350*350*535MM

|

|

Gross weight

|

7.5KGS

|

|

Number of phases

|

I/IPXO

|

|

Waterproof grade

|

2-5x 20 T8A

|

|

Fuse specifications

|

220V ,110V150HZ,60HZ

|

|

Usage environment

|

Indoor use

Altitude less than 3000m

Ambient temperature: +5 to +40°C

Relative humidity: 85%RH

Maximum voltage fluctuation: +-10%

|

Instructions For Use:

1. First make sure the device is connected to the power supply, press the power switch to position 1, the indicator light is on.

2. When the power indicator light is on and the working indicator blue light flashes, the device starts to warm up.

3. When the blue light is on, it reaches the optimum temperature, and then you can use the device.

(No blue light on) NOTE: If the seal is in the warming up stage and the handle is pressed down, an alarm will start sounding to warn that the unit is not ready. Lift the handle until it turns completely blue.

4. Insert the sealing paper underneath the platen again, however tuck the paper towards the front until the front comes out to the desired length.

5. Pass the sealing paper under the platen and press the handle back down.

6. Slide the knife holder so that the sealing paper is cut (handled simultaneously). At the end of the sealing phase, the blue LED goes out and an alarm sounds.

7. On this side the sealing is complete, turn the handle back to remove the seal and the sealer's operating indicator lights up again ready for the next package.

Warning: If the handle is pressed down and the first alarm is heard, and the handle is not turned back, then the heating unit will not work and the alarm will sound until the handle is put back in place, the heating unit will work again and it will take a few seconds to reach the desired working temperature and the working LED will come back on so that the sealing can be done again.

8. Load the instruments to be sterilised in the cut seal, load them into the heating device from the front, press down the handle again, and turn back after the new alarm sound.

9. Sealing machine factory has been debugging, according to the provisions of the implementation of the operation can meet the requirements of continuous packaging. Only when the working light is not lit need to wait a few seconds.

Common Faults & Solutions:

|

Fault Phenomenon

|

Analysis Of Causes

|

Solution

|

|

The switch indicator is off

|

1. The power supply is in the power-off state.

2. The fuse is broken.

3. The power cable is damaged

|

1. Check the power supply circuit and restore the normal power supply.

2. Check whether the fuse in the power socket is disconnected and use the spare fuse.

3. Replace the power cable

|

|

The working LED light is not displayed

|

1. The heating tube temperature has not reached the design temperature.

2. If there is no temperature on the machine, the heating tube or control board is damaged

|

1. The cooler needs to wait for about 3 minutes, and will light up after the temperature point

2. Ask electricians and other professionals to confirm whether the heating tube has voltage in the energized state, and replace the heating tube when there is voltage and no heat, and replace the control board when there is no voltage

|

|

After the handle is pressed down, there is no alarm sound after 4s

|

1. The handle is not pressed to the end

2. The internal switch or control board is damaged

|

1. Press the handle to the end, and you can hear the sound when the switch is on

2. Open the side by measuring the switch line open to confirm whether the control board or switch, line, etc

|

|

The buzzer is long

|

The handle is depressed, causing the switch to keep on

|

1. Make sure that the handle is in the upward position and is not pressed

2. Turn on the side check switch for internal compression

|