Features:

1. Highly efficient sterilisation

The dental autoclave performs specific high-efficiency sterilisation operations to ensure inactivation of stubborn heat-resistant micro-organisms such as HIV, HBV, BSE and spores, in line with the stringent requirements for medical disinfection. This sterilisation capability greatly reduces the risk of infectious pathogens and is particularly suitable for frequently used surgical and medical instruments.

2. Powerful vacuum drying system

The use of advanced vacuum drying procedures can control the residual humidity of instruments after sterilisation to less than 0.2%, effectively preventing secondary contamination and bacterial growth, and ensuring that the instruments remain dry and clean each time they are used. This vacuum drying method is especially suitable for sensitive and precise medical devices.

3. Comprehensive Sterilisation Test Function

In order to verify the sterilisation effect, the dental sterilizer supports Bowie&Dick steam penetration test, Helix spiral test and Vacuum vacuum test. Various tests can accurately assess the working status of the steriliser and verify whether the sterilisation meets the expected standards; Bowie&Dick test is used to detect steam penetration, Helix test assesses the sterilisation effect of luminal instruments and Vacuum test verifies the vacuum performance of the equipment and ensures that the equipment is in a good working condition.

4. Multiple Safety Design

In order to ensure safety, the autoclave dental is equipped with multiple safety designs, including safety valves and pneumatic locks. When there is pressure inside the equipment, the pneumatic locks will automatically lock the door cover to prevent misuse. The equipment also has an automatic fault self-testing system, which can quickly identify and provide feedback once a fault occurs, ensuring safe use and timely maintenance.

5. Automatic cleaning & maintenance programme

The autoclave dental is equipped with automatic cleaning procedure, which can clean the internal pipeline and steam generator regularly to avoid residue clogging and affecting the sterilisation effect. Every 30 times running automatically triggered cleaning, reduce the frequency of manual maintenance, to maintain the long-lasting operation of the equipment.

6. Door cover sealing adjustment system

The door cover is designed with a patented adjustment mechanism that allows the user to simply adjust the sealing degree of the door cover as needed to ensure stable air tightness during each operation. This feature can reduce the possible gas leakage in the sterilisation operation and improve the uniformity and efficiency of sterilisation.

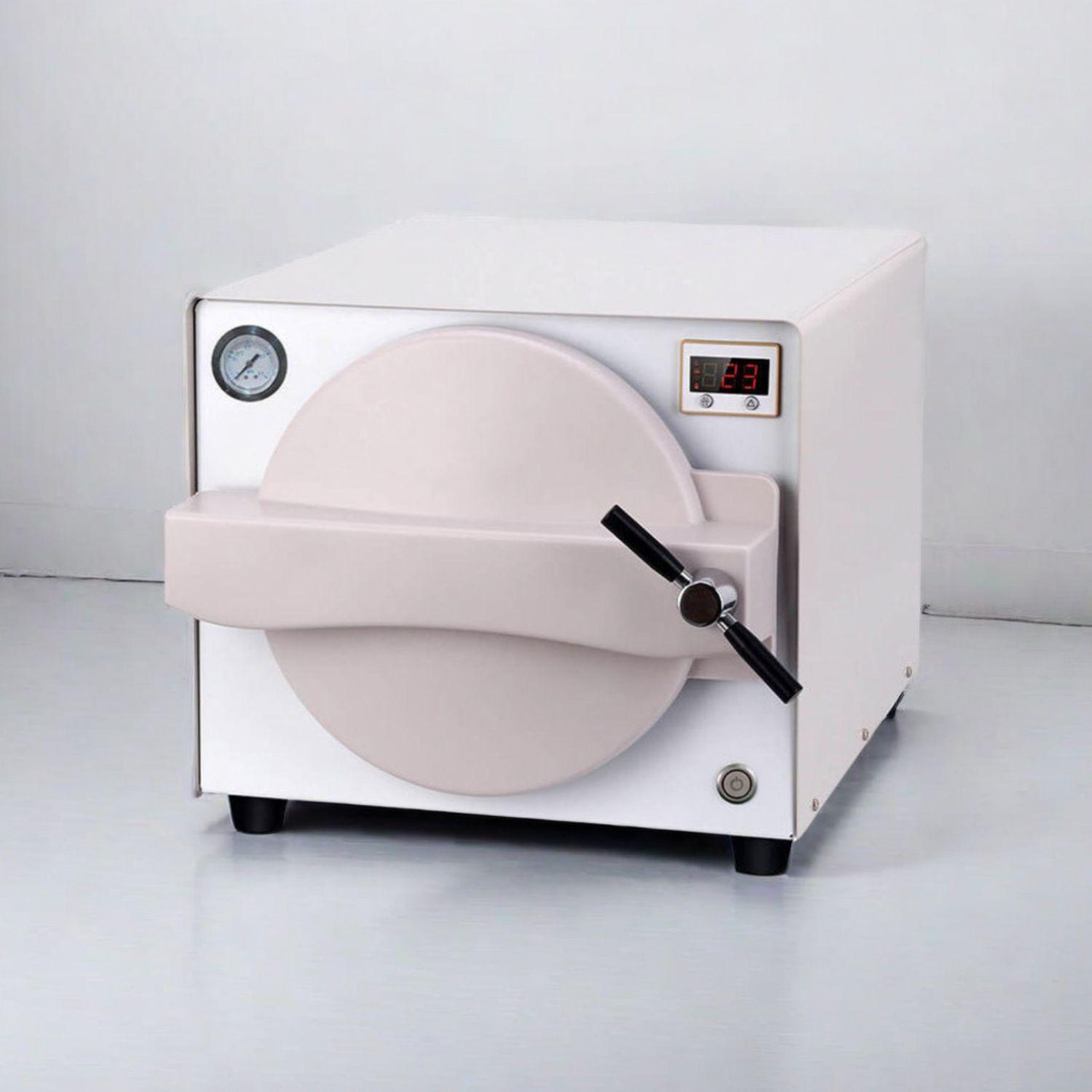

7. High-quality pot material & structure

The steriliser body is made of 2.6mm thick stainless steel, ensuring stronger corrosion resistance and pressure resistance. Unique one-time stretching moulding technology makes the pot body smooth and not easy to scale, prolongs the service life and reduces the effect of scaling on the surface of the pot body on the sterilisation effect.

Parameter:

| Rated voltage |

AC220V/50Hz |

| Rated power |

2000W |

| Door closing method |

manual |

| Sterilization cycle classification |

Class N |

| Sterilization temperature/pressure |

121℃/100~120KPa

134℃/200~220KPa

|

| Volume |

18L |

| Inner cavity size |

φ249mm X 450mm |

| Sterilization chamber configuration |

3-layer movable instrument tray, 1 instrument rack |

| Water supply system |

Clean water tank volume: 3L; Waste water tank volume: 3L |

| Appearance size |

640X445X395mm |

| Packaging size |

740X550X500mm |

| Net weight |

45kg |

| Gross weight |

53kg |

Precautions:

1. Scope of application of the product: the product is used in medical institutions for the sterilisation of pressure-resistant and high-temperature steam-resistant medical devices.

2.The maximum temperature inside the chamber is 125℃ when 121℃ sterilisation procedure is selected; The maximum temperature inside the chamber is 138℃ when choosing 134℃ sterilisation procedure.

3. When sterilising, the sterilising temperature is within the range of 0-3℃ of the set temperature.

4. Not resistant to high temperature and high pressure product sterilisation (pressure, temperature check the technical specifications).

5. This product can not be used in closed glass bottles or closed glassware and other liquid items held in the sterilisation process, because the operation of the temperature, pressure changes may lead to liquid bottles burst, so as to endanger the safety of persons and equipment.

6. Chlorine ions are important factors causing corrosion damage to stainless steel. If you use this steriliser to sterilise items containing chloride ions, you must rinse the interior wall of the steriliser with water every day to avoid corrosion of the deposited chloride ions on the internal stainless steel, affecting the service life of the product.

7. This product is only suitable for high temperature and high humidity resistant medical device box items, can not be used for petroleum jelly and other oils and powders sterilisation.

8. When sterilising, please put in the chemical indicator that meets the requirements, and carry out regular biological tests on the steriliser to monitor the sterilisation effect.

Problems & Troubleshooting:

<Cannot start the programme>

1. ‘READY’ indicator is not lit, it means that the door is not closed tightly, can not start the machine, please close the door tightly.

2. Wastewater indicator light is on, it means that the wastewater is full, please insert the attached drain pipe into the wastewater drain port, after discharging the wastewater, it can be started.

3. Water tank water shortage indicator light, that the water in the tank can not complete a cycle of sterilisation, according to the previous instructions to add water before starting.

4. After the machine alarm, you need to press and hold the start button for 8S to exit the alarm.

5. Any emergency occurs, please check the table of warning codes to solve the problem. If you can't solve it, please contact your dealer. We will try our best to provide help you in a short time. It is recommended not to open the door immediately after the machine alarm, cool it down for a while before opening the door.